Finished product will be of round pipe, square and rectangle pipe.

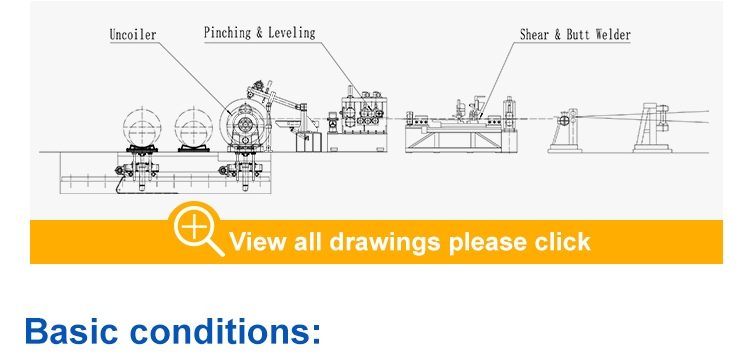

Feeding strip→ Uncoiler→ Peeler→ Five roll Flattening→ shear and end welder→ Spiral accumulator→ Forming → High-frequency induction welding→Removing External burr→ Polishing Roller→ Water Cooling→ Sizing→ Cutting Saw→ Pullout roller table→ Weighing and Measuring→ Painting and Marking→ Packing→ Warehousing

| Pipe Parameter | |

| Round pipe | Φ114mm-Φ219mm |

| Square & Rectangle pipe | 80X80mm-150X150mm |

| Pipe length | 6m |

| Packing Type | |

| Fully automatic | No seal punching type bundling machine head |

| Packing belt quantity | 4 |

| Width | 32mm |

| Thickness | 1.0mm |

| OD | 800mm |

| Width | 200mm |

| Max tension | 20000N |

| The junction plane width is not less than the belt width. The length is not less than 150mm.( The circular arc diameter is not less than Φ750mm) | |