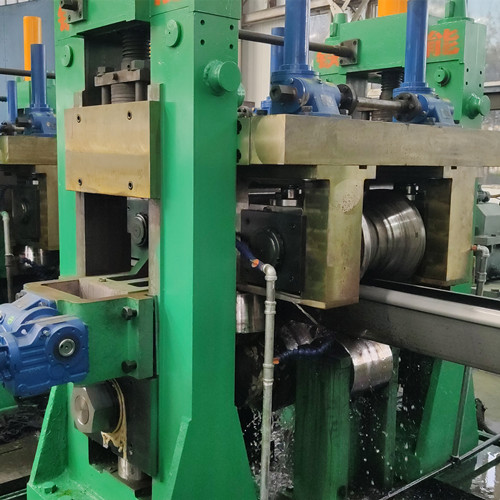

ERW610 high-frequency welded pipe production line isthe special equipment providing longitudinally welded pipeand cold formed steel forindustriessuch as metallurgy, construction, transportation, machinery, vehicles andso on.Taking cold or hot-rolled steel as raw materials,throughcold-formed and high-frequency welding method produce the suitable round tube.

Material of the coil: Hot rolled coil with natural edges or slit coil

Strip Steel: Max.X60

(I)Steel Pipe Specification

1.1 Strip steelcoil

| Type of coil | : Hot rolled coil with natural edges or slit coil |

| Coil O.D. / I.D | :Ø1500~2300mm / Ø760mm (-70/+20mm) |

| Weight of coil | : Max.35Tons |

| Strip width | : 1020~1915mm (will be cut to proper width on slitting line) |

| Tolerance of width | : Coil with natural edges: 0~+20mm (Edge miller could be used for all strip thickness range) |

| Strip thickness | : 7.0mm ~ 17.0mm |

| Tolerance of thickness | : According to the above standards |

| Strip camber | : 30.0mm in any 10.0m length |

| Coil telescope | : Mill Edge max.60mm; Slit max.30mm |

| Length of coil fish tail | : <1.0m |

1.2 Steel Pipe Specification

| No. | Product variety | Outer diameter (mm) | Thickness (mm) | Grade/ Yield strength | Standard |

| 1 | Line pipes | Ø325~610 | 7.0~17.0 | Up to X60 | API 5L |