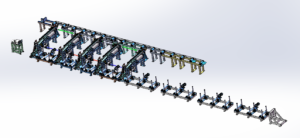

Automatic steel pipe stacking machine is used on the end of the steel pipe production line, to complete the collection and stacking the welded pipes automatically. The machine can run stable automatically, reducing the labor intensity, improving the automation level of the production line and effectively improving the production efficiency. The Machine can eliminate the impact and knocking noise of pipes, avoid scratches and bruises, improve product quality, reduce production costs, and eliminate the potential safety hazards.

This equipment is designed independently and innovatively based on the automation needs of existing pipe production lines, combined the advantages of similar foreign equipment. This machine adopts advanced technology, has safety and reliable performance, with compact and reasonable structure, mature and complete process, and convenient operation and maintenance.

| Bundle Shape | : Hexagonal Bundle, Square and

Rectangular Bundle |

| Pipe Size | : φ42-φ127mm |

| Square & Rectangular | : 30*30-100*100mm 30*50-80*120mm |

| Line Speed | : 40-80m/min |

| Pipe Length | : 3.0-12m |

| Max square bundle size | : 600*600mm |

| Min square bundle size | : 380*380mm |

| Max dimension of hexagonal bundle middle layer | : 650mm

|

| Max dimension of hexagonal bundle middle layer | : 380mm |

Pipe Feeding →Pipe Layering →Automatic Stacking Mechanism →Pipe End Alignment →Bundle Vertical Delivery →Manual Strapping/auto strapping machine →Conveyor