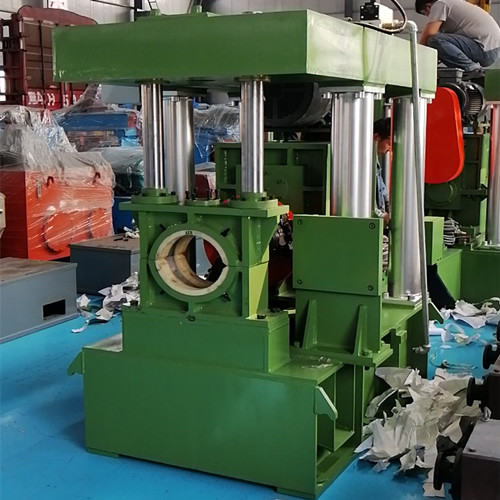

This machine is used in the production line of high-frequency pipe or seamless steel pipe. It is a special equipment for milling and chamfering the end face of steel pipe.

The machine consists of a power head, a power head feeding mechanism, a clamping mechanism, a pushing mechanism, a traverse mechanism, an electronic control system, and a pneumatic system. The clamping mechanism is driven by the cylinder; the power head is driven by the motor through the belt drive spindle, and then the cutter head is rotated; the power head is fed by the servo motor and the reducer through the ball screw; the traverse mechanism is composed of the motor, the brake, the reducer, and the step Into the organization. In the automatic working state, the movement of each component is controlled by the electric appliance and the PLC, so that the entire steel pipe flat chamfering process is automatically and continuously operated.

a. Pipe Material: Middle & Low Carbon steel (δb≤550Mpa, δs≤350Mpa)

b. O.D. of pipe: 4”~12”(114.3mm to 273mm)

c. Length of pipe: 6.0-7.3m

d. Thickness of pipe: 3.0-6.0mm

e. Speed: 6 pieces/min

f. Pipe: For round pipe only

g. Cutting: Insert type, three knives

h. End facer head quantity: 2 sets

i. Each end facer working position: 1 piece of pipe at one time