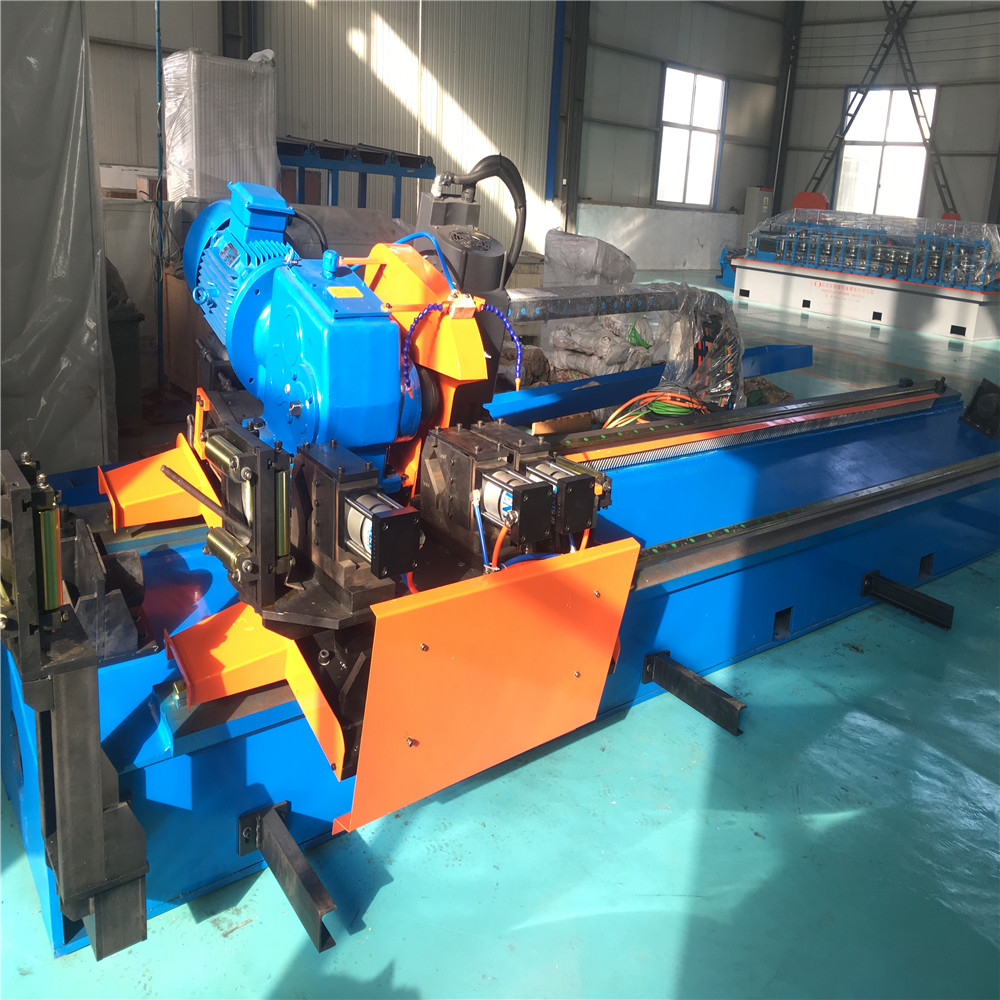

It is the mechanical equipment which used in continuously production, auto fixed ruler cutting steel pipes, is one of the important support device for weld pipe production line. It can cut pipes during static and motion status, can both cut round pipe and special pipe.

Flying cold sawing is a new online cutting technology in H.F. welded tube industry. Compare with the friction heat saw, its most major characteristic is the cold milling principle. The end of the tube is smooth and without burr after cutting off. For high quality requirements, these is no need off-line second treatment. In addition, due to the use of servo tracking technology, cutting length accuracy is higher than the traditional computer flying saw. Dust and noise pollution are obviously reduced in the production process.

{SteelTape}→→ Double-head un-coiler →→Strip-head Cutter and welder→→Spiral accumulator→→Forming section (Flattening unit +Main driving unit +Forming unit +Guide unit +High frequency induction welding unit +squeeze roller) + De-burr frame →→Cooling unit →→ Sizing unit and straightener →→Cold saw under computer-control →→ Run-out table→→ Semi-auto Packing machine

| Method of cutting | Cold cut without burr |

| Material | Carbon steel, Q235 and under. |

| Direction of operation | Right or left (as desired) |

| Max. Tube diameter | 127 mm OD |

| Min. Tube diameter | 31.5 mm OD |

| Max. Wall thickness | 5.0 mm |

| Min. Wall thickness | 1.0 mm |

| Max. Operating speed | 100m/min |

| Reference tube length | 4000-12000 mm |

| Max. Saw blade diameter | 560 mm |

| Driving motor | Servo motor 20kw |

| Feeding motor | Servo motor 5.5kw |

| Blade motor | Servo motor 24kw |

| Length measurement | 2500 pulse encoder IP65 waterproof and dust proof from Koyo |

| Max. Tube length tolerance, approx. | ±3 mm |

| Nos. Of clamping devices | 3 |

| Means of tube clamping | Hydraulic |

| Line direction | Please specify |