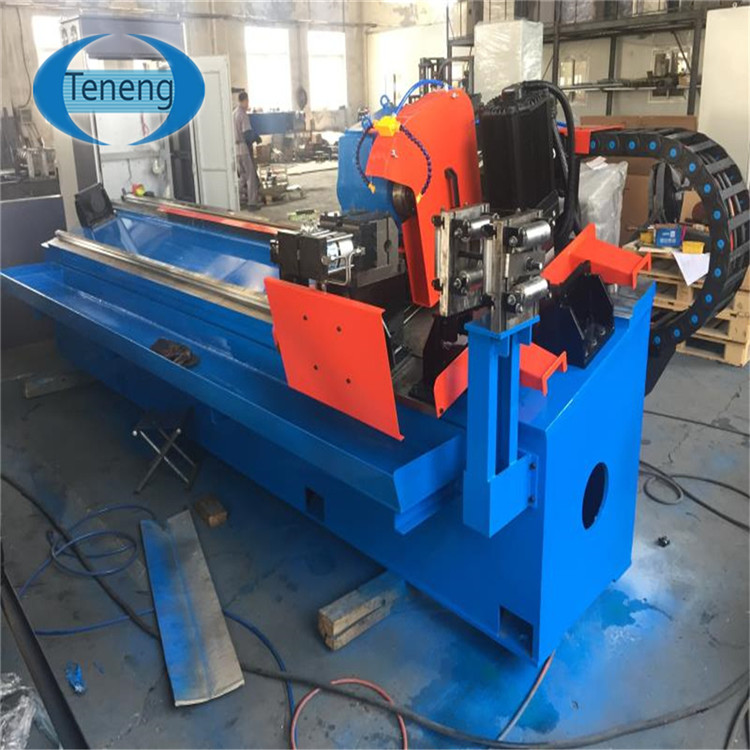

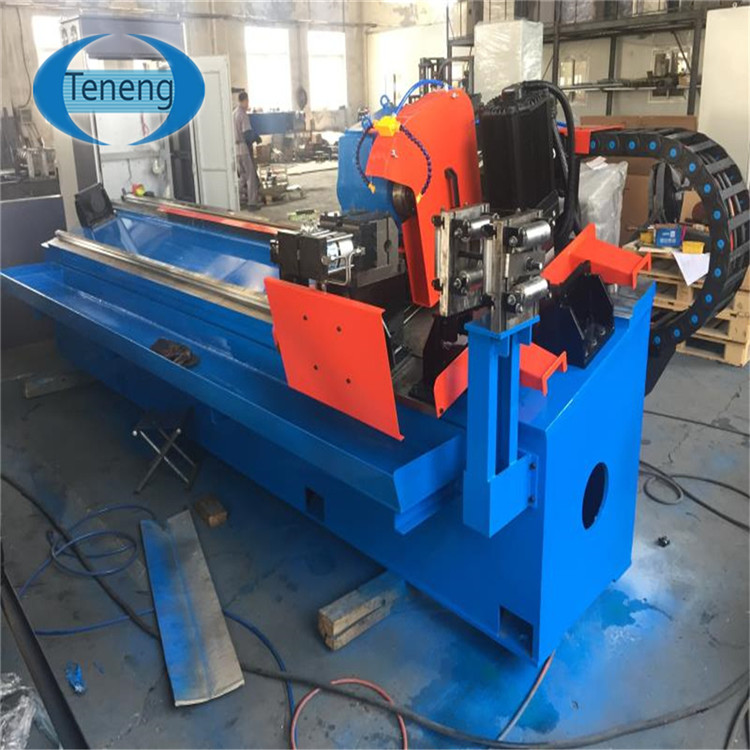

Cold saw is a new online cutting technology in H.F. welded tube industry. Compare with the friction heat saw, its most major characteristic is the cold milling principle. The end of the tube is smooth and without burr after cutting off. For high quality requirements, these is no need off-line second treatment. In addition, due to the use of servo tracking technology, cutting length accuracy is higher than the traditional computer flying saw. Dust and noise pollution are obviously reduced in the production process.

2.1.1 Scope of application: hot-rolled and cold-rolled steel (Max.Q235);

2.1.2 Pipe specification:

Round pipe: Ø50mm to Ø165mm;

Square pipe: 40x40mm up to 130x130mm;

Rectangular pipe: 40х50mm to 100х160mm;

Cutting range: 6000mm-12000mm;

Cutting accuracy (range length): +/ – 1.5 mm;

Inside bead NOT removing.

2.1.3 Mill line: Direction from left or right ;

21.4 Cutting length: 6.0-12.0mm

2.1.5 Length precision: ±1.5mm (line speed fluctuating less than 2%)

2.1.6 Cutting speed: Max.40 m/min

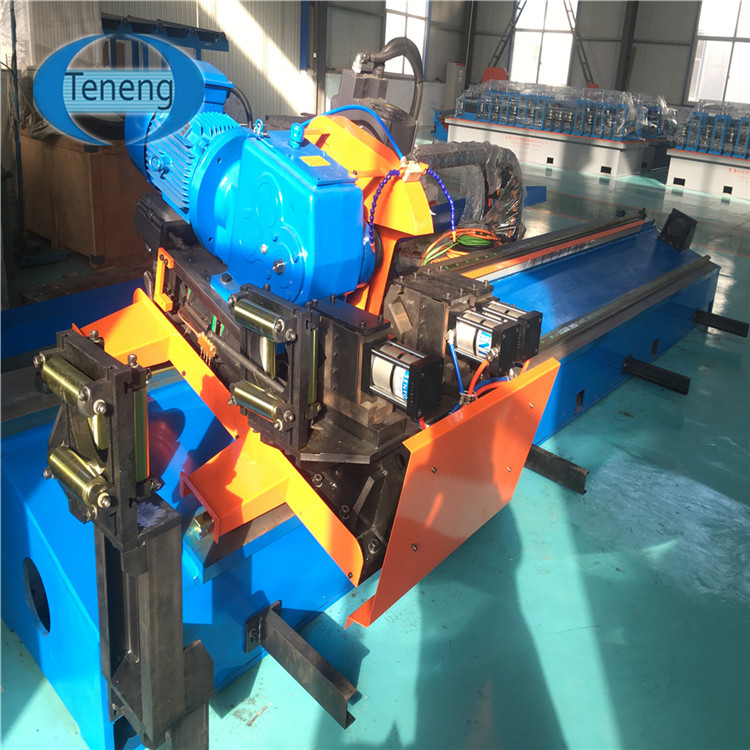

2.2.1 Driving motor: servo motor 22KW, from YASKAWA, Japan.

2.2.2 Feeding motor: servo motor 5.5KW, from YASKAWA, Japan.

2.2.3 Blade motor: AC motor 26KW, SIEMENS, CHINA.

2.2.4 Length measurement: 2500 pulse encoder. IP65 waterproof and dustproof from Koyo

2.2.5 Control cabinet: 2200*800*600mm, Operating desk: 1100*900*700mm.