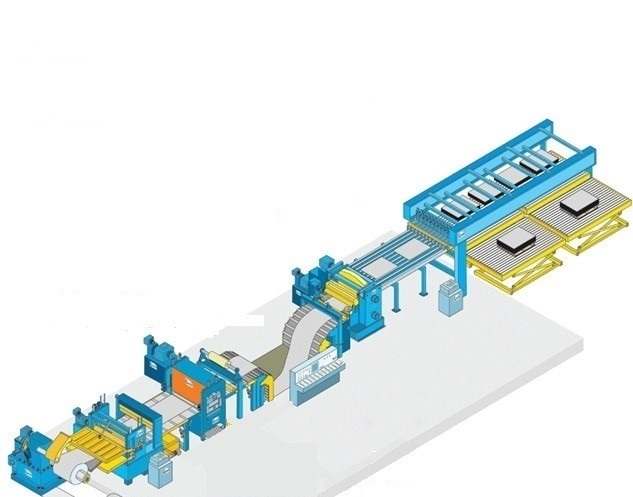

Uncoiler→ shovel board device → Flattening →Accumulator→Centering device→Fixed length and feeding device →cutting machine→convey table→ Precision leveler→ sending roller→Stacking Frame

| Raw material: | Black steel,blue steel, galvanized steel,cold-rolling steel, prepainted steel, pickling coil |

| Thickness of steel strip: | 0.4~3.2mm |

| Width of steel strip: | 800~1500mm |

| Inner diameter of strip coil: | Φ508-Φ610mm |

| Outer diameter of strip coil: | Φ1000-Φ1800mm |

| Max quantity of strip coil: | 30 tons |

| Cut Length: | 500~6000mm |

| Cut Accuracy: | ±1.0mm |

| Speed: | Max 60m/min |

| Input Power: | 380 Volt, 3 phase, 4 lines, 50Hz. |

| Feeding Direction: | Left side or right side |

| Cutting line technical style: | Automatic fixed length and feeding feed length, fixed shear. |

| Composition | 1. V-shape coil storage 2. Coil loading cart 3. Hydraulic double head uncoiler 4. Feeding conducting plate device 5. Pinch device 6. Fifteen-roll straightening machine quadruple style 7. Mid-bridge 8. Side guiding positioning device 9. Five-roll precise leveler 10. Pinch sizing device 11. Transverse shear 12. Delivery platform 13. Hydraulic loading lifting platform 14. Unloading stand 15. Unloading Car 16. Hydraulic and pneumatic system 17. Electric control system |