High-frequency welding H-type production line

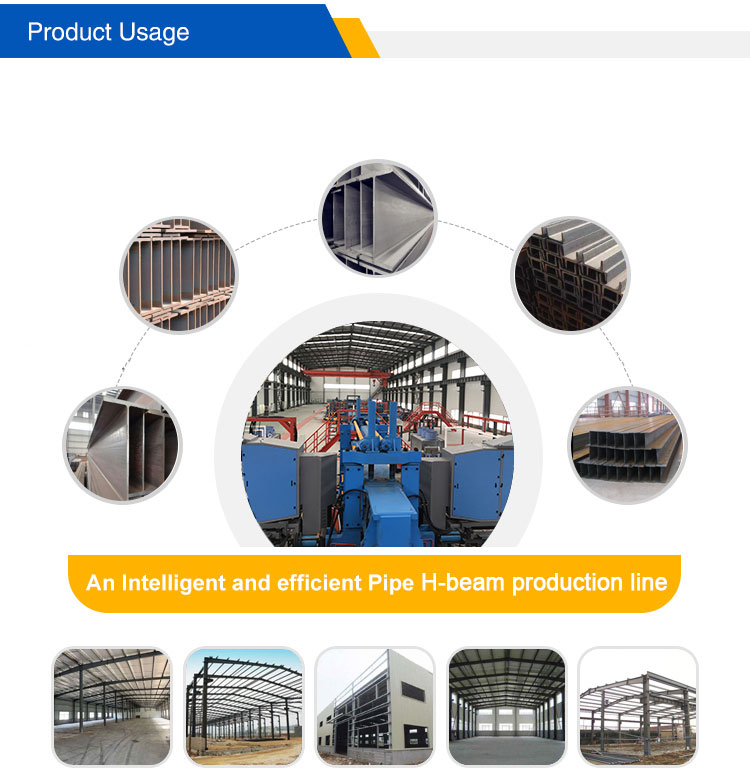

H.F. welding light H-beam applied in various fields, such as light-steel workshop, venues, residence, office building, prefabricated house, garage, agriculture greenhouse, container frame and with the merits of light weight, high stiffness, good quality, nice appearance, convenient construction, short project period and etc.

H.F. welded thin H-beam is energy saving and sustainable recycling and reusing which accords to the high efficiency and economy of scientific development view, also a widely applied building material.

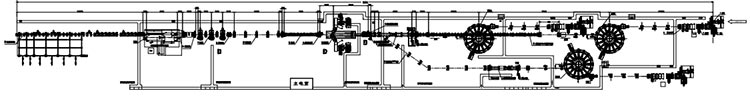

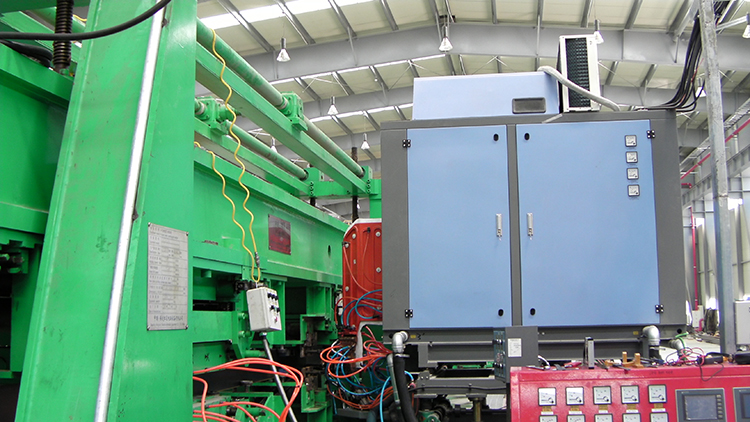

H.F. welding light H-beam production process is as follows. Two pcs of flanges steel strip and one piece of web plate steel strip which were pre-cut as per product specification, after web plate upset forging by vertical machine unit, then initiate the three pcs as H-type structure, then two H.F. welder carry out H.F. induction welding to the joint of upper & lower flange and web plate. Welding method is contact. (H.F. welding light H-beam adopts two major peculiarities of “skin effect” and “proximity effect” from H.F. current, puts two contact pins minimum impedance channel of welded material by conduct contacting, that is all current flow on the open-vee formed by upper & lower flange and web plate to centralize welding power on the open-vee, and realize H-beam welding with less power.)

1.1. Technical features for H.F. welding light H-beam

1.1 Fast welding speed, high automatization grade.

1.2 Small heat affection zone, easily control H-beam distortion.

1.3 Different materials combination of H-beam welding can be realized.

1.4 Realizing mini-tension production and reducing welding stress.

1.2. Presently technical level of H.F. welding H-beam production Line

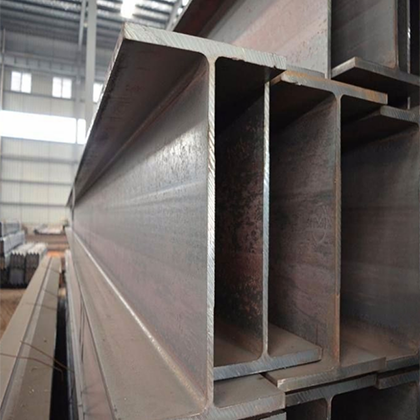

1.2.1 High precision of cross section dimension

Due to the high quality steel coil, the cross section shape precision is excellent; this makes the structure assemblage more convenient.

1.2.2 High cross section performance

The thickness ratio between flange and web plate can be enlarged, compared with hot rolling steel, under the same conditions it can be produced as components like high anti-bending, high performance of cross section, and lighter when the cross section performance is the same.

1.2.3 Cross section size customized by customer

Production as customer appointed cross section dimension, also the special type of H-beam (unequal width of upper & lower flange, unequal thickness of upper & lower flange).

1.2.4 Metallographic structure equalization of welding part performance.

Structure homogeneous fusion of web material and flange material.