The mill is intended for manufacturing of round pipe of Φ12-Φ50mm with thickness of 0.5-2.0mm from cold-rolled and hot-rolled coil strip by means of unclosed tubular blank with its subsequent welding into tube, edge heating by means of solid state high-frequency welder, longitudinal seam welding in rolls of tube welding machine, cooling, further sizing or shaping and on-stream cutting of endless tube in measured lengths.

Finished product will be of round, square or rectangular pipe.

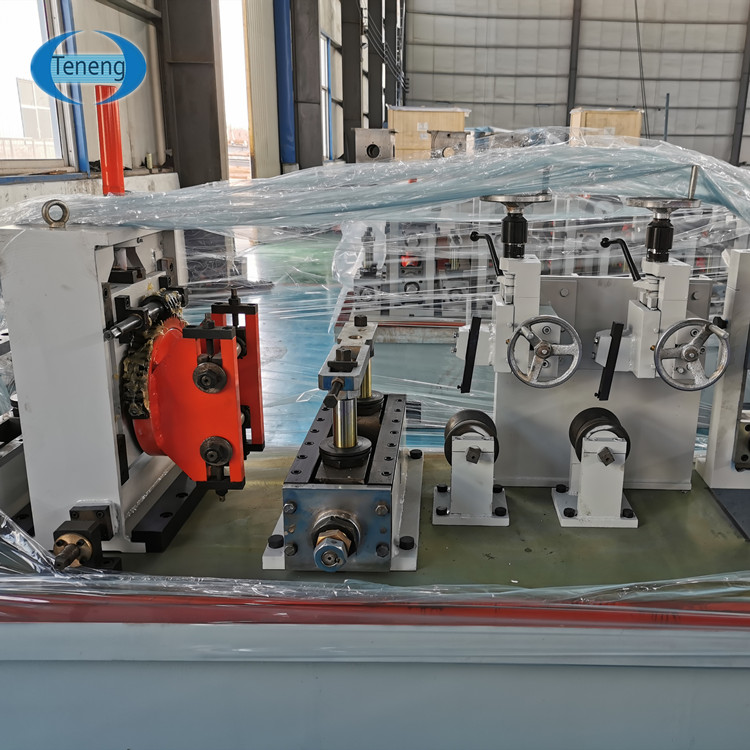

{SteelTape}→→ Double-head un-coiler →→Strip-head Cutter and welder→→Spiral accumulator→→Forming section (Flattening unit +Main driving unit +Forming unit +Guide unit +High frequency induction welding unit +squeeze roller) + De-burr frame →→Cooling unit →→ Sizing unit and straightener →→Cold saw under computer-control →→ Run-out table→→ Semi-auto Packing machine

| Steel Pipe Specification | |

| Round Pipe diameter | Φ12–Φ60mm |

| Pipe Thickness | 0.5 – 2.0mm |

| Square and rectangle pipe | 10X15-50X50mm |

| Pipe Thickness | 0.5 – 2.5mm |

| Pipe Length | 6-12m |

| Length Tolerance | 0-6mm |

| Steel Tape Specification | |

| Material | Carbon steel (δb≤500Mpa, δs≤235Mpa) |

| Inner diameter | Φ470-Φ510mm |

| Outer diameter | Φmax=1800mm |

| Strip steel width | 40mm-60mm |

| Strip steel thickness | 1.2mm-4.0mm |

| The maximum weight | 1.5.0 tons |

| Electric installed capacity | appro.250KW |

| Line Speed | 30-90m/min |